WP1. TECHNICAL COORDINATION & ECONOMIC MANAGEMENT

(workload PRT: 1.3 pm)

B&O: This WP entails all the coordination actions between members of the RST and the stakeholders. The two PIs of the project have leaded many previous regional, national and EU projects, as well as companies contracts. Because of that, they are experienced in coordination actions and the activities proposed in this WP, together with those of WP2, will assure a well-controlled flow of knowledge within SetEDEN2Diesel. On the other hand, the more and more time-consuming administrative duties related to the research management of a project have oblied to quantify the time efforts dedicated to this administrative work, much of them not directly related to research. All this time is considered in WP1 and consists of: (1) selection and hiring of early stage researchers; (2) economic tracking of the activities; (3) writing technical and economic reports. Tasks included in this WP are coordinated by one of the PIs and involved to all RST. In case of any contingency, the other PI will take the responsibility.

T1.1: Management of Scientific Coordination.

T1.2: Hired researchers management.

T1.3: Cost management.

T1.4: Preparation of scientific and technical follow-up reports for the Spanish Agency of Research.

T1.5: Preparation of economic follow-up reports for the Spanish Agency of Research.

T1.6: Intelectual property management.

WP2. KNOWLEDGE MANAGEMENT

(workload PRT: 1.3 pm)

B&O: In this WP all dissemination and technology transfer activities are included, as well as other ways of valuing of the obtained results for the Society. To reach this goal, there are several tasks that go from the development of a website aimed to spread knowledge to Society up to the organization of the Workshop SetEDEN2Diesel, that aims to integrate research groups and stakeholders into a discussion forum on the most recent progress of topics investigated in the project (not only fundamentals but also the investigated applications), aiming for internationalization of the research interest in the topic and for knowledge transfer that stimulates the production fabric. It also includes scientific coordination meetings among researchers and also with supporting stakeholders and other external companies or organizations interested in the project. It is also included a task related to the coordination of the scientific dissemination in scientific meetings and also the compilation of all research works into the ZENODO repository, in order to satisfy the legal requirement of open acces publication without charging excessively to the economy of the project. It will also be evaluated which publications are worth to be golden-access, for which a budget has been applied in this proposal. Additonaly, special attention will be paid to data management plan in task 2.7 to ensure access to research data so that it can be used, reused and distributed. Tasks are coordinated by one of the PIs and involved to RST. In case of any contingency, the other PI will take the responsibility of this WP.

T2.1: Coordination of knowledge obtained in the project.

T2.2: Website development and maintenance.

T2.3: Organization of an international scientific Workshop.

T2.4. Final report and preparation of next proposals.

T2.5: Dissemination coordination.

T2.6. Open access dissemination of research outcomes.

T2.7. Data Management Plan.

WP3: DEVELOPMENT OF COMPONENTS OF THE HYBRID ENGINE

(4.1 PM)

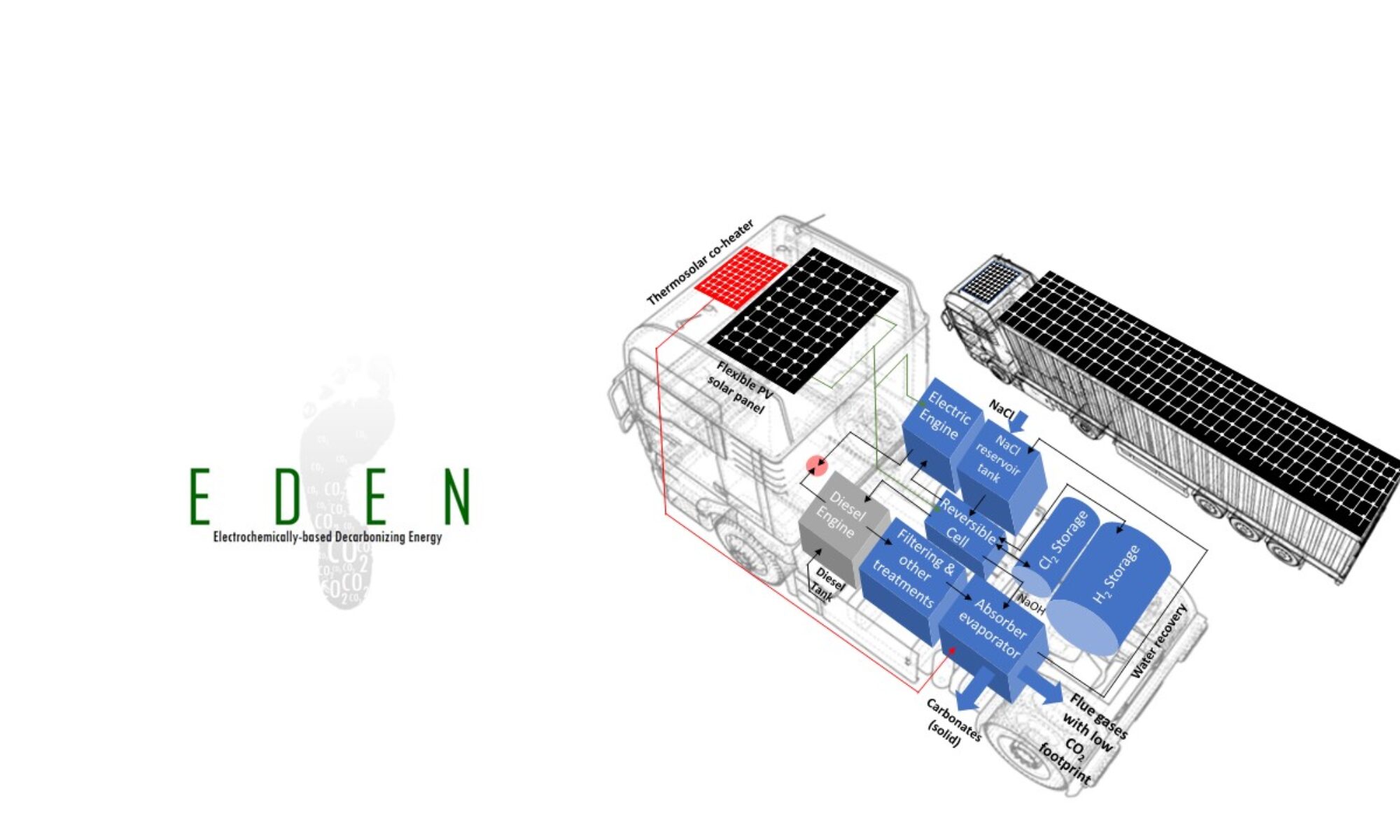

B&O: The aim is to adapt and optimise EDEN® technology (developed incipiently during the EXPLORA CTQ2017-91190-EXP project for its application in WWTPs) to the smart and sustainable energy supply of automotive sector. This WP addresses the problem at a TRL of 4. Both the electrolytic and fuel cell processes will be developed and evaluated in a first phase separately and with continuous power supply in the case of the electrolyser, but later they will be integrated, developing reversible electrochemical cells, for which several 3-D printed prototypes will be built and equipped with the best electrodes and membranes determined in the electrolyser and fuel cell studies. It will be assessed for the fuel cell stage whether it is better to use chlorine as a comburent or whether it is replaced by air, converting chlorine into a saleable product. We already have the technology developed at TRL3, but we have to improve performance and parameters such as thickness and composition of membranes and formulation/loading of catalysts, operation temperature and pressure will be studied to improve the current results and adapt them to the special characteristics of transport sector. For the evaluation of the conversion of CO2 into carbonates/bicarbonates, pipetail streams obtained from small diesel engines will be used and the soda solution generated in the electrolysers fed with the salt streams, introducing selected flowrates of both streams into spray columns whose outlet is connected to an electrical evaporation and condensation system that allows the solids (carbonates and salts) to be separated from the water. In a final phase of this activity, its performance will be studied with stream profiles directly from solar panels. Electric heating will also be used in this WP for evaporation as the information obtained is much more important to close balances.

T3.1. Development of electrolysers for energy regulation systems.

T3.2. Development of fuel cells for energy regulation systems

T3.3. Development of reversible cells for energy regulation systems.

T3.4. Engine exhaust gas absorption.

T3.5. Process integration with solar energy.

WP4: INTEGRATION OF COMPONENTS, SCALE-UP & PROOF OF CONCEPT

(2.9 PM)

B&O: The objective of this work package is to address the scaling of the processes that have been developed in WP3 and their integration. The TRL level to be reached in this WP is 5 (tested in the real environment) as a first trial to approach TRL6 (tested in the expected environment close to the expected performance), considering that it is intended to transcend from the laboratory to the companies, as it has been done in previous proposals, without reaching yet in the framework of this project the real application, for which it would be necessary an additional effort and a larger funding than requested and a vision above what is funded in the call. The technology developed in WP3 will be evaluated in a remotely piloted truck equipped with two sets of driving wells one connected to a fuel engine and the other with an electric engine. The truck prototype will be manufactured in collaboration with MCG and MFM that are integrated into the support team and are industrial engineers working as profesor of vocational training in automobile technology in the IES “Maestre de Calarava”. They will take care of implementeing a “small” diesel and electric engine into the traction system of the truck prototype and will collaborate in the integration of the other elements of the EDEN® technology. A reversible electrochemical cell will be designed, manufactured and connected to the electric engine as well as the other elements. As well, the pipetail will also be connected to the absortion column of the EDEN device. Gases are not the same of those obtained in WP3 but from the integration point of view, the approach is more than enough as to get the relevant information needed and obtain a first estimation of the integration. This WP interacts strongly with WP5, providing valuable data for LCA and using the energy management software developed for this application.

T4.1:Prototype desing & manufacture

T4.2: Adjusting the prototype by integration of technologies

T4.3: Testing the prototype in different weather conditions

WP5. DEVELOPMENT OF ENERGY MANAGEMENT MODELS AND SUSTAINABILITY ANALYSIS

(4.2 PM)

B&O: This WP is transversal to the whole project and has a twofold objective: (1) to gain in-depth knowledge of the process by obtaining mathematical models of its different elements and to develop a simulator to optimise the energy management of the truck and (2) to analyse the real sustainability of the proposal by means of life cycle analysis (LCA) life cycle cost (LCC) For the first objective, the aim is to develop a mathematical simulator of the two energy regulation processes that includes solar radiation prediction, energy generation and management, and carbon sequestration. This type of model has already been successfully developed in previous projects of our team, allowing the optimisation of the use of solar energy. With the help of this simulator, the case study planted in WP4 will be designed and operated. The second objective seeks to maximise the eco-efficiency of the technologies developed. The aim is to make the most of all resources, both material and energy, and the most appropriate alternatives depending on the characteristics obtained from the different products. Alternatives will be evaluated to minimise the cost of environmental improvement and the environmental intensity of the technologies studied. The eco-efficiency concept will include the analysis of cost, energy consumption and storage, carbon and water footprint, raw materials involved and by-products generated. This activity provides an extreme level of coordination. What to do with each of the products of the process will be assessed by determining what is the best option for the solid generated with carbonates and salts, whether deep burial or use as feedstock in the context of the circular economy. Also, what to do with Cl2 and HCl. Thus, the feasibility of the alternative use of Cl2 will be evaluated, assessing not only its use as a comburent, but also as a commercial product. Morover, we go beyond and to complement the environmental LCA and LCC a Social LCA (S-LCA) will be also made to assess the social and sociological aspects.

T5.1 Modelling for energy management

T5.2. Sustainability analysis and optimisation.