Planificación

WP1. TECHNICAL COORDINATION and ECONOMIC MANAGEMENT

(workload PRT: 1.0 pm)

This WP entails all the coordination actions between members of the RST and the stakeholders. The two PIs of the project have leaded many previous regional, national and EU projects, as well as companies contracts. Because of that, they are experienced in coordination actions and the activities proposed in this WP, together with those of WP2, will assure a well-controlled flow of knowledge within NEAT4SUST+. On the other hand, the more and more time-consuming administrative duties related to the research management of a project have oblied to quantify the time efforts dedicated to this administrative work, much of them not directly related to research. All this time is considered in WP1 and consists of: (1) selection and hiring of early stage researchers; (2) economic tracking of the activities; (3) writing technical and economic reports. Tasks included in this WP are coordinated by one of the PIs and involved to all RST. In case of any contingency, the other PI will take the responsibility.

R: MAR (0.4 pm)

RTM: JLB(0.2 pm) JLL (0.2 pm) CMF (0.2 pm)

STM: ESR1 ESR2 CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

IP:Q1-Q12

WP2. KNOWLEDGE MANAGEMENT

(workload PRT: 1.0 pm)

In this WP all dissemination and technology transfer activities are included, as well as other ways of valuing of the obtained results for the Society. To reach this goal, there are several tasks that go from the development of a website aimed to spread knowledge to Society up to the organization of the Workshop NEAT4SUST+, that aims to integrate research groups and stakeholders into a discussion forum on the most recent progress of topics investigated in the project (not only fundamentals but also the investigated applications), aiming for internationalization of the research interest in the topic and for knowledge transfer that stimulates the production fabric. It also includes scientific coordination meetings among researchers and also with supporting stakeholders and other external companies or organizations interested in the project. It is also included a task related to the coordination of the scientific dissemination in scientific meetings and also the compilation of all research works into the RUIDERA repository, in order to satisfy the legal requirement of open acces publication without charging excessively the economy of the project. It will also be evaluated which publications are worth to be golden-access, for which a budget has been applied in this proposal. Tasks included in this WP are coordinated by one of the PIs and involved to all RST. In case of any contingency, the other PI will take the responsibility of this WP. R: JLB (0.4 pm)

RTM: MAR(0.2 pm)

JLL (0.2 pm)

CMF(0.2 pm)

STM: ESR1 ESR2 CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

IP: Q1-Q12

WP3. DEVELOPMENT OF ATMOSPHERIC ELECTRO-ABSORBERS

(workload PRT: 4.0 pm)

This WP is commited to the development of systems operating at near atmospheric pressure conditions, oriented to the removal of VOCs and deodorization of gaseous waste streams. TRL level aimed for this WP is 4 (Built in a laboratory environment) and, taking that into account, synthetic model gas streams are going to be used instead of real gaseous streams in this WP. As model of VOC polluted streams, it is going to be used streams of air polluted with benzene, aniline, vinyl chloride and acetaldehyde. As a model of an odour streams, air streams polluted with hydrogen sulfide, ammonia and methyl-mercaptane will be used. Gaseous streams will be made by stripping liquid solutions containing the pollutants in order to properly simulate real production. Technology approach proposed is based on the combination of an absorber with an electrolyzer. As absorbers, paked column and jet mixers are proposed for this WP. Electrolysis, single and coupled with UV and/or US will be tested for degradation of pollutants. All plants needed are in operation now, although they will be optimized in a first task. As absorbents-electrolytes, aqueous and methanol solutions containing mediators (Co, Ag, …) will be used, being one of the key expected inputs, together with the electrode type for each of the model gases whose treatment aims to be evaluated and optimized.

R: MAR(2.3 pm)

RTM: JLB (0.3 pm) JLL (0.5 pm) CMF (0.9 pm)

STM: ESR1 CAM EVS RSB GCS

IP: Q1-Q8

OE: 4 RSP

TRL: 4

WP4. DEVELOPMENT OF PRESSURIZED ELECTRO-ABSORBERS

(workload PRT: 4.8 pm)

Electrochemical cells to obtain highly value-added oxidants from oxygen oxidation and / or reduction will be developed in this WP. Particularly, the direct production of ozone, and a process to produce chlorine dioxide from electrochemically generated hydrogen peroxide have been targeted as objectives. This project starts from a high level of development in the generation of H2O2, which is intended to be further optimized with this WP with the design of cells capable of operating at very high pressures and connectable with cryostats, designed for the ultimate purpose of increasing as much as possible the solubility of gases in the liquid electrolyte. It is also intended to optimize the integration of processes. Composition of the anode and cathode material, formulation of the electrolyte, electrochemical cell mechanical design and operation conditions are the key parameters for the efficient simultaneous production of H2O2 and chlorate (needed for ClO2) and ozone. TRL level aimed for this WP is 4 (Built in a laboratory environment) using commercial technology from external suppliers and in-house mechanical design for the cells and high pressure mixers.

R: JLL (3.0 pm)

RTM: MAR (0.4 pm) JLB (0.2 pm) CMF (1.2 pm)

STM: ESR2 CEB GRM OSC GCS

IP: Q1-Q8

OE: 3 RSP

TRL: 4

WP5. DEVELOPMENT OF MIXED ELECTROABSORBERS

(workload PRT: 4.1 pm)

The aim of this WP is the development of mixed electro-absorbers based on the production of tiny micro-bubbles of the target gas into the electrolyte by means of an abrupt change in pressure attained with an special mechanical device consisting of a high-pressure mixer and a valve. Target applications are related to the storage of energy with the development of regerative cells for the thermoelectrochemical Westinghouse and for H2-Cl2 processes, allowing the use of biphasic mixtures, which becomes an important issue because of the solubility of the reagents used in the Westinghouse (SO2/H2) and chloroalkaline (Cl2/H2) processes, which is affected by the severe pH conditions. TRL level aimed for this WP is 4 (Built in a laboratory environment). There are setups ready for these activities, although small adaptations are needed as pointed out in the budget

R: JLB (2.0 pm)

RTM: JLL (1.2 pm) CMF (0.5 pm) MAR (0.4 pm)

STM: ESR1 AJM MRL GCS

IP:Q1-Q7

OE: 2 RSP

TRL: 4

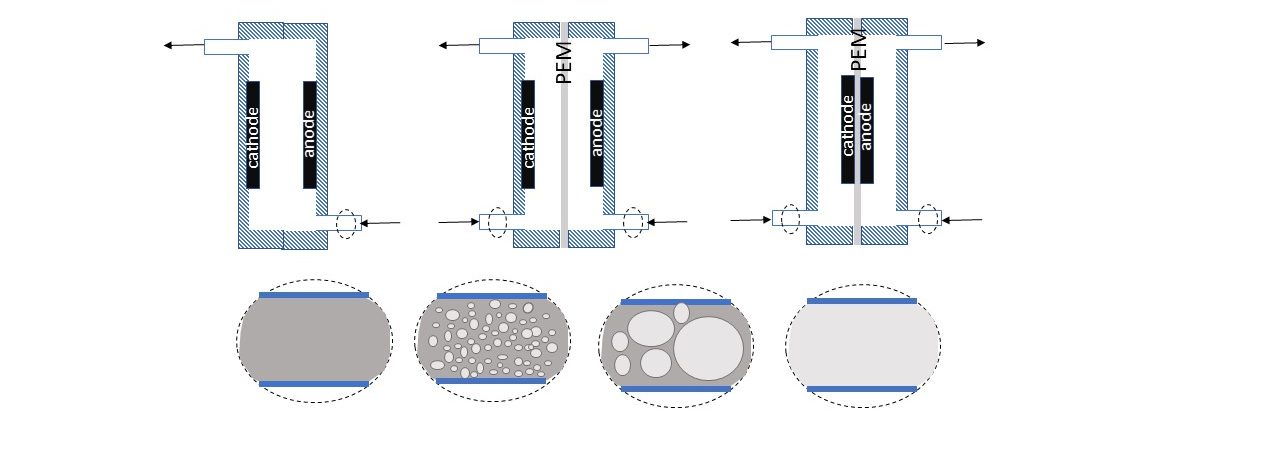

WP6. ASSESSMENT OF GAS PHASE ELECTROCHEMICAL PROCESSES

(workload PRT: 2.7 pm)

Some of the electrochemical processes cannot be operated only in gas phase (hydrogen peroxide and by-products generation, chloro-alkali regenerative cell) but there are others that can be operated only in gas phase. These gas-phase based electrochemical technologies will be compared, in order to gain expertise and knowledge to assess when the concept gas-liquid is interesting and when the direct treatment in gas phase using a solid electrolyte in between the electrodes of the cell is better. In all cases, a standard gas/gas PEM electrochemical cell will be used for the gas treatment. This WP will provide WP7 for the relevant inputs needed to face the LCA. TRL level aimed for this WP is 4 (Built in a laboratory environment) and the main aim is to obtain relevant data which allows the comparison of technologies with WP3, 4 and 5. A lower research effort is needed, because in fact it is an extension of the work developed in WP3 to 5 with a different setup.

R: JLB (1.0 pm)

RTM: MAR (0.6 pm) JLL (0.3 pm) CMF (0.8 pm)

STM: ESR1 ESR2 JCR GCS

IP: Q3 Q9

OE: 3 RSP

TRL: 4

WP7 ENERGY AND SUSTAINABILITY MANAGEMENT

(workload PRT: 5.3 pm)

In the last projects of our group, different possibilities for powering the electrolytic remediation of water and soil with renewable energy have been optimized using in-house software tools and storage of surplus energy in Redox Flow Batteries (RFB). In this WP, we intend to go another step beyond, applying all the technology to one of the new systems developed in the project (the removal of VOCs/Odour using atmospheric electroabsorbers), as well as studying the influence of power supply with variable patterns in operation, in a systematic way (defining four behavior profiles: solar-winter, solar-summer, wind-Beaufort force 4-5, wind-Beaufort force 6-7) that will be applied for periods of two weeks. In addition, all the technologies developed will be analyzed as a whole, throughout the use of eco-efficiency tools, carbon footprint analysis, energy analysis and the evaluation of uses of the different by-products, to determine what is needed to achieve optimal technology not only from the viewpoint of economy but also of sustainability. TRL level aimed for this WP is 5 considering that we are using real data in all tools.

R: CMF(3.0 pm)

RTM: MAR (0.9 pm) JLB (1.1 pm) JLL (0.3 pm)

STM: ESR1 ESR2 CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

IP: Q1-Q11

OE: 10 RSP

TRL: 5

WP8 SCALE UP OF THE DEVELOPED TECHNOLOGIES

(workload PRT: 3.8 pm)

It is aimed to face the scale up of the processes that have exhibited the best performance in WP3-WP6. TRL level aimed for this WP is 5 (Tested in intended environment) reaching in some cases 6 (Tested in intended environment close to expected performance) taking into account that we aim to transcend from lab to companies, as we have done before in previous proposals. Given the time constraints and the cost of each of the tests carried out with the large facilities (in both personal & consumable costs), there will be no scaling up of all technologies but only those that exhibit the best performance. A priori, it is intended that the applications will be treatment of a real waste gas stream, chlorine dioxide production and chloroalkaline energy storage, although it is risky to take this decision at this time and it can be modified depending on the results obtained in WP3-WP6, always selecting one application in each WP. Hence, if necessary, the processes scaled-up will be conveniently readjusted. There is previous experience of the RTM in scaling up and in the operation of large-scale infrastructures.

R:MAR(1.0 pm)

RTM: JLB (1.1 pm) JLL (1.3 pm) CMF (0.4 pm)

STM: ESR1 ESR2 CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

IP: Q8-Q12

OE: 3 RSP

TRL: 5

Progreso de los paquetes de trabajo a fecha mitad de proyecto (diciembre 2021)

WP1: Coordinación Técnica y gestión económica

Miembros del equipo participantes*: R: MAR; RTM: JLB; JLL; CMF; STM: RGF IFM JIE CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

Todas las tareas de coordinación técnica y económica incluidas en este paquete de trabajo se están desarrollando de acuerdo con la programación propuesta. La Tarea T1.1 (Gestión de la coordinación científica) se ha desarrollado según lo programado con reuniones cuatrimestrales de coordinación administrativa que se han hecho coincidir con las científicas tecnológicas de la T2.1. La T1.2 (Gestión de investigadores contratados) ha conllevado la gestión administrativa de cuatro contratos de investigadores para colaborar en las distintas actividades del proyecto, según se explica en otros apartados de esta memoria. La T1.3 (Gestión de costes) ha conllevado el seguimiento de todas las partidas económicas y la evaluación de las adquisiciones para una correcta administración económica de la subvención asignada al proyecto. Las T1.4 y T1.5 (Preparación de informes científico- tecnológicos y económicos) se está completando mediante esta actuación. La T1.6 (Gestión de la propiedad intelectual) no ha sido necesaria.

WP2: Gestión del conocimiento

Miembros del equipo participantes*: R: JLB; RTM: MAR; JLL; CMF; STM: RGF JIE IFM CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

Todas las tareas de coordinación de la gestión del conocimiento incluidas en este paquete de trabajo han sido desarrolladas de acuerdo con la programación propuesta. La T2.1 (Gestión del conocimiento) se está desarrollando adecuadamente mediante las reuniones cuatrimestrales. La T2.2 sobre desarrollo y mantenimiento de la web se ha desarrollado adecuadamente y ya está operativa la página web (blog.uclm.es/proyectoneat4sust). La T2.3 (organización de workshop internacional) está actualmente en preparación, pero no está programada (de acuerdo con la solicitud) hasta la tercera anualidad al igual que la T2.4 (Preparación del informe final y de nuevas propuestas). No obstante, en relación con el proyecto ya se ha participado en la redacción de varias propuestas para proyectos europeos. La T2.5 (Coordinación de la diseminación) ha permitido gestionar adecuadamente 30 publicaciones e 34 presentaciones en congreso y la T2.7 (acceso abierto) está actualmente en desarrollo. Varios artículos han sido publicados completamente en abierto y para el resto se está gestionando su aparición en repositorio Ruidera una vez que se cumplan los periodos de embargo.

WP3: Desarrollo de electro-absorbedores atmosféricos

Miembros del equipo participantes*: R: MAR; RTM: JLB; JLL; CMF; STM: RGF MMM FED ANA PMC JMH LAG FLS CAM; EVS RSB GCS; En este paquete de trabajo se desarrollan las actuaciones para alcanzar el Objetivo 1 y los resultados en forma de publicaciones y congresos se han expuesto en la sección anterior. Se ha completado la Tarea 3.1 (Desarrollo de sistemas columna de absorción electrolizador) y se está trabajado en la Tarea 3.2 (sistema de electroabsorbedor jet). Ambos tipos de tecnologías han sido estudiados utilizando tolueno y percloroetileno como contaminantes modelo. Actualmente se están evaluando otros contaminantes y completando el diseño de distintos sistemas de electroabsorción para conseguir incrementar su eficiencia. En la solicitud del proyecto se comprometió la preparación de 4 informes o artículos científicos como consecuencia de esta actividad. En el momento actual se han publicado 7 artículos directamente relacionados, cinco derivados a partir de investigación inducida y se han presentado 13 contribuciones en congreso.

WP4: Desarrollo de electro-absorbedores presurizados

Miembros del equipo participantes*: R: JLL; RTM: MAR; JLB; CMF; STM: MCS MAM MMM MRP JMH MSM FLS GAS CEB GRM OSC GCS El paquete de trabajo desarrolla el Objetivo 2 del proyecto y consta de tres tareas. En el momento actual se ha completado las Tareas 4.1 (Optimización de la producción electroquímica de peróxido de hidrogeno) en cuanto a lo proyectado inicialmente. No obstante, se sigue trabajando en el tema por ser de gran interés avanzar por encima de los inicialmente objetivado y tener mucha relevancia en otros proyectos que actualmente desarrolla el grupo (Proyecto SERPIC). Se está trabajando en las Tareas 4.2 (Producción electroquímica de ozono) y 4.3 (Producción electroquímica de dióxido de cloro), estando ambas muy avanzadas y habiendo obtenido en las tres resultados publicados en bibliografía. En la solicitud del proyecto se comprometió la preparación de 3 informes o artículos científicos. Hasta el momento se han publicado 7 artículos directamente relacionados, uno derivado y se han presentado 6 contribuciones en congreso.

WP5: Desarrollo de electro-absorbedores intermedios

Miembros del equipo participantes*: R: JLB; RTM: JLL; CMF; MAR; STM: RGF MCS AJM MRL GCS El paquete de trabajo desarrolla el objetivo 3 del proyecto y consta de dos tareas. Se ha avanzado sustancialmente en la tarea 5.1 (Desarrollo de una celda regenerativa para procesos Westinghouse) y en la 5.2 (Desarrollo de una celda regenerativa cloroalcalina). Los resultados alcanzados han sido mucho más interesantes en la Tarea 5.2 que en la 5.1. Esta tarea 5.2 está conectada con un proyecto Explora recientemente acabado (CTQ2017-91190-EXP) y los óptimos resultados están dando lugar a la solicitud de nuevos proyectos y al registro de la marca comercial EDEN ® para la tecnología desarrollada en el EXPLORA y que ahora se está mejorando en el marco del proyecto NEAT4SUST+. En la solicitud del proyecto se comprometieron 2 informes o artículos científicos. Hasta el momento, se han publicado 5 artículos.

WP6: Evaluación de procesos electroquímicos en fase gas

Miembros del equipo participantes*: R: JLB; RTM: MAR; JLL; CMF; STM: RGF MCS MAM RDM JCR GCS

Este paquete de trabajo desarrolla el Objetivo 4 del proyecto. Se ha comprobado la tecnología para eliminación ambiental de gases (en el marco de la Tarea 6.1 tratamiento de VOCS y olores), pero debido a la dilución de las corrientes los resultados alcanzados no han sido los esperados. Por este motivo se han modificado esta actividad con la introducción de una tecnología de adsorción y electrolisis en metanol que sí ha ofrecido unos resultados muy interesantes que están en vías de publicación. Se ha trabajado también para para proceso de producción de ozono en fase gas (Tarea 6.2), también con rendimientos inferiores a lo esperado. En cuanto a la tarea T6.3 (celda regenerativa para proceso Westinghouse) las condiciones de operación drásticas del proceso Westinghouse y los buenos resultados del proceso cloroalcalino han hecho que nos hayamos replanteado esta actividad hacia la comparación con la celda cloroalcalina. No obstante, se han realizado todos los experimentos comprometidos. En la solicitud del proyecto se comprometieron 3 informes o artículos científicos. Hasta el momento, se han publicado 3 artículos y se han presentado 5 comunicaciones.

WP7: Gestión de la energía y de la sostenibilidad

Miembros del equipo participantes*: R: CMF; RTM: MAR; JLB; JLL; STM: RGF MCS FED FLS CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

Este paquete de trabajo desarrolla el objetivo 5 del proyecto (Sostenibilidad) y parte del 6 (modelado para la comprensión del proceso). De acuerdo con la programación propuesta se está trabajando en las tareas 7.3 (análisis y optimización de la sostenibilidad) y 7.4 Comprensión mediante modelado), habiéndose obtenido resultados relevantes en ambas que está ya publicados y quedando todavía experimentación pendiente, de acuerdo con lo proyectado. También se está comenzando a trabajar en tareas 7.1 (alimentación directa de procesos electroquímicos mediante energía renovables) y 7.2 (regulación del suministro energético mediante baterías de flujo redox). Estas dos tareas estaban programadas para ser empezadas en la segunda mitad del proyecto, pero se ha aprovechado el impulso adquirido al final del proyecto Sustertech4ch para avanzarlas lo máximo posible. En la solicitud del proyecto se comprometieron 10 informes o artículos científicos. Hasta el momento, se han publicado 7 artículos y se ha presentado 10 contribución en congreso.

WP8: Escalado de las tecnologías desarrolladas

Miembros del equipo participantes*: R: MAR; RTM: JLB; JLL; CMF; STM: RGF MCS IFM JIE CAM EVS GCS RSB AJM OSC MRL CEB GRM JCR

Este paquete de trabajo desarrolla el objetivo 6 (escalado) y tiene prevista su realización entre los cuatrimestres 8 y 12. No obstante hemos empezado con trabajo previo desarrollando celdas especiales para el proceso de electroabsorción y de ozonización que ya se han materializado en publicaciones tal y como ha sido señalado en el apartado anterior. En la solicitud del proyecto se comprometieron 3 informes o artículos científicos. Hasta el momento, se ha publicado 1 artículo.