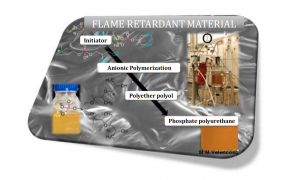

FUNCTIONALISED POLYETHER POLYOLS FOR SMART POLYURETHANES

From comfort to insulation plus the sealant, coating and adhesive applications, few families of products based in a common chemistry like the polyurethanes can find such a wide range of applications.

Our research group is investigating in the incorporation of different functionalities that provides the polyol with intrinsic fire retardancy, antibacterial, self-reconformation or dye properties.

For instance phosphorylated glycerol was used as initiator for the synthesis of polyether polyols. Also, functionalization based in Click Chemistry (1,3-dipolar cycloaddition of azides and alkynes) has been used to synthesize polyols with fluorescent properties or high thermal stability.

Also, copolymers from ethylene oxide (EO) and propylene oxide (PO) functionalized with glycidyl propargyl ether (GPE) are being synthesized. The GPE allows further attachment of drugs based in Click Chemistry (1,3-dipolar cycloaddition of azides and alkynes).

Selected Publications:

- Borreguero, A.M., Velencoso, M.M., Rodríguez, J.F., Serrano, Á., Carrero, M.J. & Ramos, M.J. 2019, “Synthesis of aminophosphonate polyols and polyurethane foams with improved fire retardant properties”, Journal of Applied Polymer Science, vol. 136, no. 29.

- Carrero, M.J., Borreguero, A.M., Rodríguez, J.F. & Ramos, M.J. 2020, “Different drug incorporation routes in ethylene oxide based copolymers”, Polymer International, vol. 69, no. 4, pp. 387-396.

- de Haro, J.C., Rodríguez, J.F., Pérez, Á. & Carmona, M. 2016, “Incorporation of azide groups into bio-polyols”, Journal of Cleaner Production, vol. 138, pp. 77-82.

- M. Velencoso, M. J. Ramos, A. Serrano, A. de Lucas, J. F. Rodríguez. Fire retardant functionalized polyol by phosphonate monomer insertion. Polymer International. 2015. 54(12), 1706-1714.

- M. Borreguero, P. Sharma, C. Spiteri, M. M. Velencoso, M. S. Carmona, J. E. Moses, J. F. Rodríguez. A novel click-chemistry approach to flame retardant polyurethanes. Reactive and Functional Polymers. 2013. 73(9), 1207-1212.

Patents:

- M. Velencoso, M. J. Ramos, J. C. García-Martínez, A. de Lucas y J. F. Rodríguez. Phosphate polyol and method of obtaining. Application number: 201031958. Spain. 2010. University of Castilla-La Mancha.

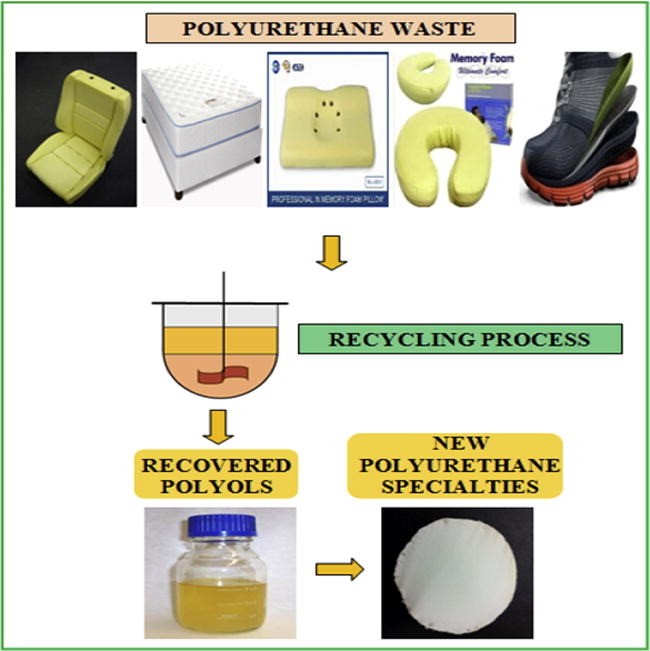

RECYCLING OF POLYURETHANE FOAMS BY GLYCOLYSIS

The main objective of this research line is the study and development of processes for the chemical recovery of the materials composing the polyurethane wastes.

Our research efforts in the PU recycling has been mainly based on using glycols as deploying agents, in such a way that the hydroxyl groups of the glycol cause an exchange in the urethane bond, the polyol being released into the reaction medium, generating “split phase” by using an excess of glycol. With very simple further treatments high quality recovered polyol can be obtained in the upper phase, being possible to take advantage of the rich isocyanate by-products accumulated in the bottom phase.

The group is involved from 2019 in the H2020 EU-funded project PUReSmart, PolyUrethane Recycling towards a Smart Circular Economy that unlocks methods of transforming polyurethane into a more sustainable material. The PUReSmart project aims to go one step further the previous advancements. By introducing new building blocks into the chemical backbone of polyurethane, a novel material will be created: covalently adaptable polyurethanes, or CAPUs.

Selected Publications:

- Simón, D., Borreguero, A.M., de Lucas, A. & Rodríguez, J.F. 2018, “Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability”, Waste Management, vol. 76, pp. 147-171.

- Simón, D., de Lucas, A., Rodríguez, J.F. & Borreguero, A.M. 2017, “Flexible polyurethane foams synthesized employing recovered polyols from glycolysis: Physical and structural properties”, Journal of Applied Polymer Science, vol. 134, no. 32

- Simón, D., de Lucas, A., Rodríguez, J.F. & Borreguero, A.M. 2016, “Glycolysis of high resilience flexible polyurethane foams containing polyurethane dispersion polyol”, Polymer Degradation and Stability, vol. 133, pp. 119-130.

- Simón, D., Rodríguez, J.F., Carmona, M., Serrano, A. & Borreguero, A.M. 2018, “Glycolysis of advanced polyurethanes composites containing thermoregulating microcapsules”, Chemical Engineering Journal, vol. 350, pp. 300-311.

- Simón, M. T. García, A. de Lucas, A. M. Borreguero, J. F. Rodríguez. Glycolysis of flexible polyurethane wastes using stannous octoate as the catalyst: Study on the influence of reaction parameters. Polymer Degradation and Stability. 2013. 98, 144-149.

Patents:

- Process for The Recovery of Reusable Polyols from Polyurethane Foams using a Novel Catalyst. de Lucas, C. Molero, J.F. Rodríguez y M. Malaga. EP 05380026, European Union. 2005. Propietary: REPSOL QUIMICA S.A.

FROM PASSIVE HOUSE CONCEPT TO ACTIVE ENERGY STORAGE AT HOME BY USING MICRO/NANOCAPSULES WITH THERMAL STORAGE CAPACITY

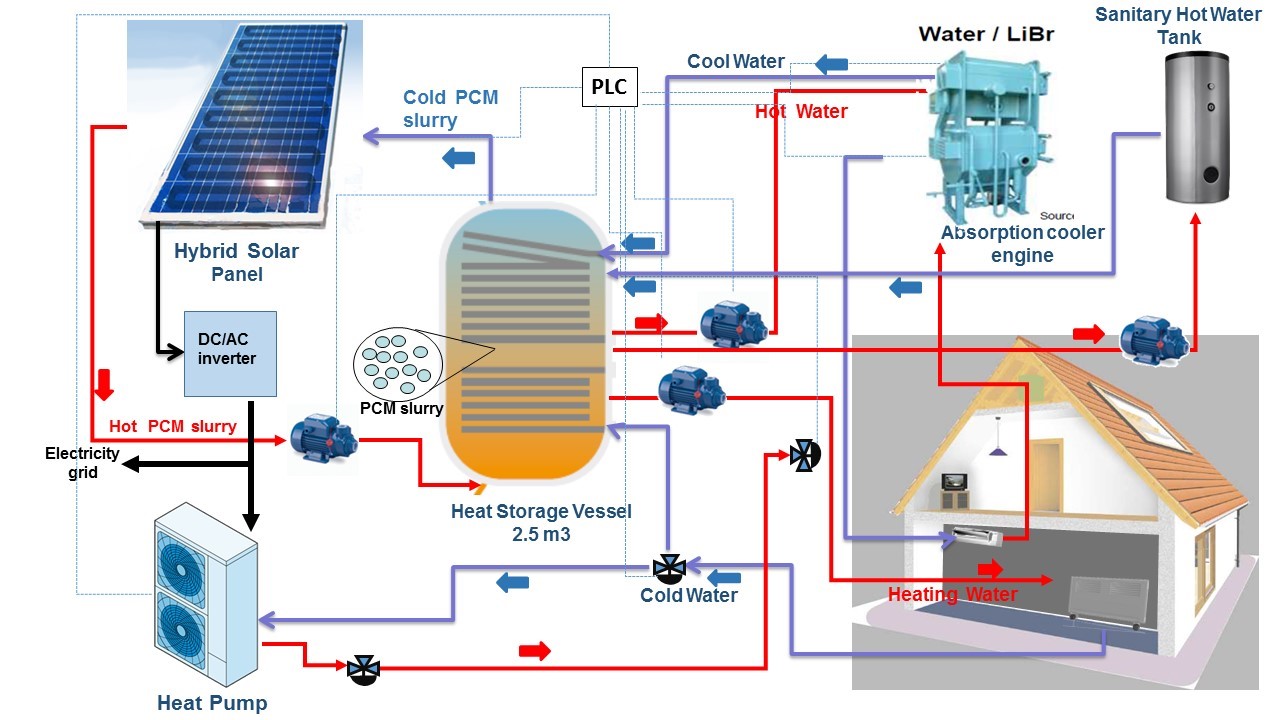

The use of renewable energy systems for energy saving applications is very important due to ecological considerations. In order to reduce environmental problems caused by high energy consumption, it is necessary to develop alternative energy saving systems. Phase-change materials (PCMs) can reversibly absorb and release energy corresponding with their latent heat and can therefore be utilized to reduce the energy demand. This way, their incorporation into buildings presents economic and environmental advantages and can contribute to the development of zero-energy houses.

There are different alternatives for the PCMs incorporation, being their previous microencapsulation and further mixture with the building materials one best options. Among the microencapsulation techniques, suspension polymerization is one of the most commonly used, being a well-known and robust technique. On the other hand, the physical microencapsulation technique of spray-drying minimizes the waste generation and the loss of the raw material and allows to obtain a product with the desired particle size.

Typical building envelope materials such as gypsum, concrete or rigid polyurethane foams have been additivated with both types of microcapsules. Suitable performance of these materials was obtained even with microcapsules contents around 50 wt%.

Beyond the concept of the incorporation of TES materials into the building envelope materials would be the concept of active energy accumulation in slurries with improved heat storage capacity with respect to pure water. Slurries containing microencapsulated PCM (MPCS) can be implemented as Heat Transfer Fluid in solar thermal collectors and/or hybrid photovoltaic-solarthermal (PV/T). Our group has developed highly concentrated slurries with nanocapsules containing phase change (NPCSs) in just one step where the whole reactant mass constitutes the thermal fluid. The slurry owns a large particle concentration greater than 35%, large stability and low viscosity. A prototype of solar plant has been built at our Institute flat roof to demonstrate the thermal abilities of such slurries.

Selected Publications:

- Pilehvar, S., Sanfelix, S.G., Szczotok, A.M., Rodríguez, J.F., Valentini, L., Lanzón, M., Pamies, R. & Kjøniksen, A.-. 2020, “Effect of temperature on geopolymer and Portland cement composites modified with Micro-encapsulated Phase Change materials”, Construction and Building Materials, 252.

- Cao, V.D., Pilehvar, S., Salas-Bringas, C., Szczotok, A.M., Bui, T.Q., Carmona, M., Rodriguez, J.F. & Kjøniksen, A.-. 2019, “Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications”, Solar Energy, 178, pp. 295-307.

- Cao, V.D., Salas-Bringas, C., Schüller, R.B., Szczotok, A.M., Hiorth, M., Carmona, M., Rodriguez, J.F. & Kjøniksen, A.-. 2018, “Rheological and thermal properties of suspensions of microcapsules containing phase change materials”, Colloid and Polymer Science, 296, no. 5, pp. 981-988.

- Serrano, A.M. Borreguero, I. Garrido, J.F. Rodríguez, M. Carmona. Reducing heat loss through the building envelope by using polyurethane foams containing thermoregulating microcapsules. Applied Thermal Engineering. 2016. 103, 226-232.

Patents:

- Process for microencapsulation of phase change materials, microcapsules obtained and uses thereof”. F. Rodríguez, M. L. Sánchez, P. Sánchez, A. de Lucas, M. L. Torres. Patente de la Unión Europea. Propietary: ASINTEC-UCLM, WO2007107171A1, EP1994063A1, CN101437854A, (2007).

- Procedimiento para el microencapsulado de materiales de cambio de fase mediante secado por pulverización. Carmona, A.M. Borreguero, J.L. Valverde, J.F. Rodríguez. Date of filing: 13-05-2008/OEPM. Spanish Patent No. P200801360

- Procedure for microencapsulation of phase change materials by sparring-drying. Grávalos, I. Calvo, J. Mieres, J. Cubillo, A.M. Borreguero, M. Carmona, J.F. Rodríguez, J.L. Valverde. Date of Filing: 26-02-2009. Priority: ES/12.05.08/ESA 200801360. European Patent No. 09153793.6-1213.

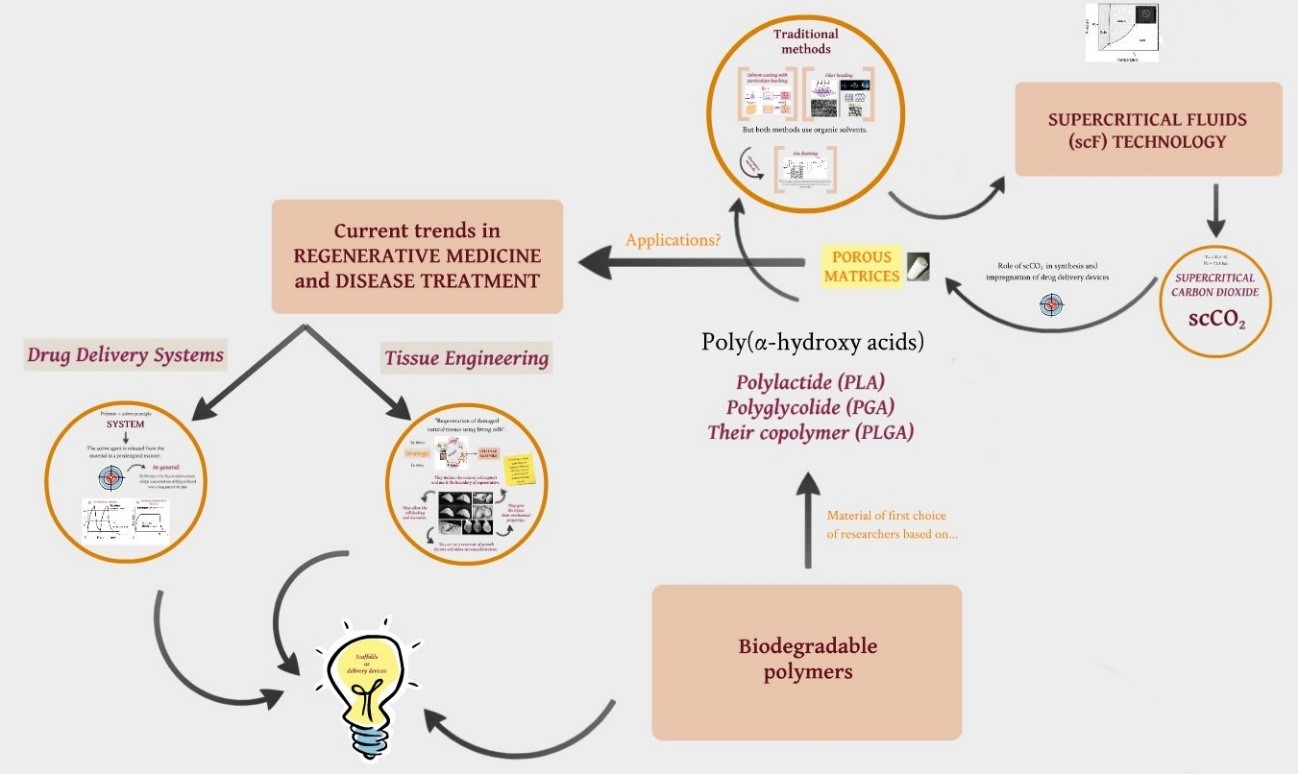

GREEN SYNTHESIS AND FUNCTIONALIZATION OF BIOPOLYMERS USING SUPERCRITICAL CO2

Biobased plastics and composites have gained significant interest during the last years. Compared to petroleum-based synthetic polymers, biobased polymers from renewable resources, such as plants and crops, can be naturally recycled by environmental processes. In this way the limited natural resources are preserved, and greenhouse gas emissions reduced. In addition, most of the biopolymer and biomedical devices are based on bioplastics. The quality and purity specifications of such biomedical purpose plastics are very exigent, so their production must be as clean as possible. For that reason, supercritical CO2 (scCO2) is finding application in the production of pharmaceutical related products due to their ability to solve difficult process, as particulation, foaming and formulation problems.

The use of scCO2 as polymerization or functionalization media looks very attractive because ideally makes easier the separation of unreacted monomers, allows a clean and complete removal of co-solvents or reaction additives, improves the mass transfer into a high swelled polymer bulk and permits the tuning of the final physical properties of the polymer obtained.

Nevertheless, not everything are advantages, the scCO2 plays a key role into the polymerization process producing multiphase reaction processes of high complexity and also in the case of certain polymers as polylactic takes part in the polymerization process generating side reactions, mainly transesterifications and thermal non-radical random chain scission of difficult control.

Using a polymer synthesized or not in scCO2 a functionalization or impregnation with a drug has to be done to provide the biopolymer with therapeutic abilities. The impregnation of drugs as additional step in the preparation of a polymeric substrate for the controlled delivery of drugs participates also of the same advantages and difficulties than the polymer synthesis in scCO2. The plastization effect that scCO2 exerts on the polymer favours greatly the homogeneous diffusion of the drug into the polymer matrix. The drug solubility in scCO2 and the drug compatibility with the substrate are parameters that has be known to get a suitable impregnation of the drug into the polymer in scCO2.

Among different techniques for polymer functionalization where toxic organic solvents are used, click chemistry emerged as one of the most promising reactions because it is classified as a very specific, efficient and versatile reaction which allow to obtain high products yields. When click functionalization is performed in scCO2, the use of harmful solvents is completely avoided, getting similar reaction rates and yields than in conventional organic solvent. But the complete elimination of the catalyst remained being an unsolved issue. The use of copper wire bits as simple catalyst in a click chemistry reaction using supercritical CO2 allows to remove the whole amount of catalyst in the final product with a simple purification step using a green solvent as scCO2 to synthetize the desired polymer-drugs adducts.

Selected Publications:

- Álvarez, I., Gutiérrez, C., de Lucas, A., Rodríguez, J.F. & García, M.T. 2020, “Measurement, correlation and modelling of high-pressure phase equilibrium of PLGA solutions in CO2”, Journal of Supercritical Fluids, vol. 155.

- Álvarez, I., Gutiérrez, C., Rodríguez, J.F., de Lucas, A. & García, M.T. 2020, “Production of biodegradable PLGA foams processed with high pressure CO2”, Journal of Supercritical Fluids, vol. 164.

- Gracia, E., García, M.T., Borreguero, A.M., De Lucas, A., Gracia, I. & Rodríguez, J.F. 2017, “Functionalization and optimization of PLA with coumarin via click chemistry in supercritical CO2”, Journal of CO2 Utilization, vol. 20, pp. 20-26.

- Gracia, E., García, M.T., De Lucas, A., Rodríguez, J.F. & Gracia, I. 2020, “Copper wire as a clean and efficient catalyst for click chemistry in supercritical CO2”, Catalysis Today, vol. 346, pp. 65-68.

- Gracia, E., García, M.T., Rodríguez, J.F., de Lucas, A. & Gracia, I. 2018, “Improvement of PLGA loading and release of curcumin by supercritical technology”, Journal of Supercritical Fluids, vol. 141, pp. 60-67.

DEVELOPMENT OF MICROPARTICLES AND MICROCAPSULES FOR THE SELECTIVE REMOVAL AND SEPARATION OF ACTIVE COMPOUNDS FROM AQUEOUS, NON-AQUEOUS AND BIOLOGICAL FLUIDS

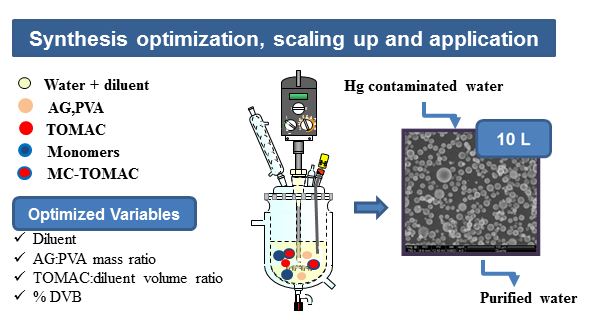

Solvent extraction and ion exchange are the most commonly used techniques for industrial separation and recovery of heavy metals. However, these have several advantages and drawbacks. The main objective of this research line is the development of processes based conceptually on traditional mass transfer process as ion exchange and adsorption but improved through the development of specially designed particles for each specific purpose.

Our group has developed a new material concept consisting in microcapsules with the size of an ion exchange resin constituted by a functionalized permeable shell to the ions and containing as core a highly selective extraction agent for the metal of interest. The synthesis of microcapsules is carried out by suspension like polymerization. These “extractioncules” possess the properties of the best selective agent and the best chelating resin with any of the problems of solvent and agent losses and emulsion formation. Such extractioncules were specifically designed for the removal of mercury from surface, drainage and ground waters and the demonstration of their performance in the decontamination of natural waters from Almaden mining area.

On the other hand, traditional ion exchange materials has been applied to the removal of natural compounds from fermentation or waste streams.

Selected Publications:

- Á. Alcázar, A.M, Borreguero, A. de Lucas, F.J. Rodríguez, M. Carmona. Microencapsulation of TOMAC by suspensión polymerisation: Process optimisation. Chemical Engineering Research and Desing. 2017.117, 1-10.

- Á. Alcázar, C. Gutiérrez, A. de Lucas, M. Carmona, J.F. Rodríguez. Equilibrium treatment for highly selective sulfonated microcapsules containing Di(2-ethylhexyl)phosphoric Acid. Industrial and Engineering Chemistry Research. 2016. 55(4), 1033-1042.

- Á. Alcázar, I. Garrido, E.M. García, A. de Lucas, M. Carmona, J.F. Rodríguez. New type of highly selective microcapsules for the removal of mercury from Surface polluted waters. Separation and Purification Technology. 2015. 154, 55-262.

- Á. Alcázar, M. Carmona, A.M. Borreguero, A. de Lucas, J.F. Rodríguez. Synthesis of microcapsules containing different extractant agents. Journal of Microencapsulation. 2015. 32(7), 642-649.

- Sánchez-Silva, Á. Alcázar, A. de Lucas, M. Carmona, J.F. Rodríguez. Functionalization of microcapsules for the removal of heavy metal ions. Journal of Chemical Technology & Biotechnology 2011. 86(3), 437−446.

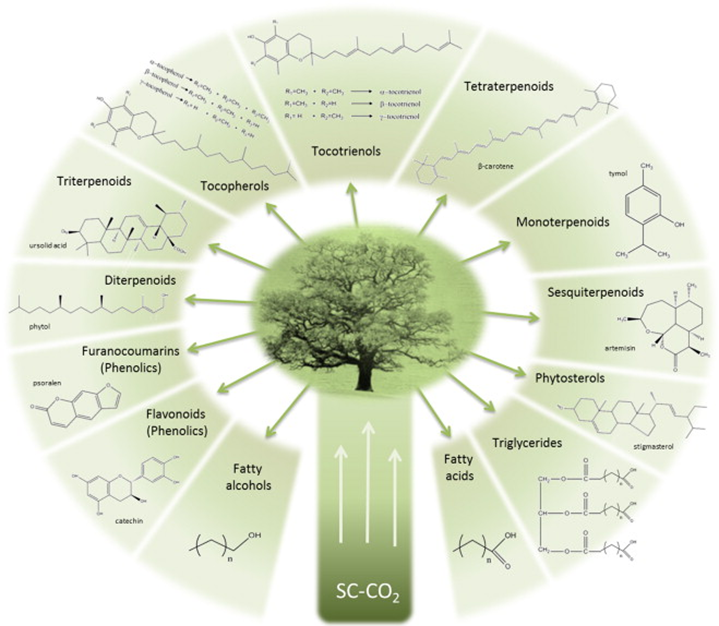

SEPARATION AND CONCENTRATION OF NUTRACEUTICALS, ACTIVE COMPOUNDS AND ESSENTIAL OILS FROM AGRO-FOOD SOURCES USING scCO2

Supercritical fluid extraction is an environmentally friendly “green” processing technique that replaces the traditional organic solvent based extraction techniques with more benign solvents like carbon dioxide. The use of CO2 as a solvent in pharmaceutical and food industry has advantages over other solvents because CO2 is non-toxic, non-flammable, noncorrosive, inexpensive and readily available in large quantities. In addition, the supercritical fluids instead of conventional organic solvents have several advantages like higher purity extracts, no residual solvent, single step processing, reduced operating costs, selective fractionation, faster separation and physiologically compatible. Also, Supercritical fluid extraction (SFE) has gained increasing attention over the traditional techniques, like steam distillation since protects extracts from thermal degradation.

This technology can be used to increase the competitiveness of the agro-food industries by extraction of high added value substances present in their products and wastes. Agricultural raw materials and their waste products from the wine sector, aromatic herbs and garlic industry (Vitis vinifera, Lavandula sp., Allium sativum) have been extracted and purified by several methods. From these extractions and purifications, compounds with pharmacological activity as antioxidants and anti-inflammatory have been produced in our laboratories.

Selected Publications:

- Perez-Ortiz, J.M., Galan-Moya, E.M., de la Cruz-Morcillo, M.A., Rodriguez, J.F., Gracia, I., Garcia, M.T. & Redondo-Calvo, F.J. 2020, “Cost effective use of a thiosulfinate-enriched allium sativum extract in combination with chemotherapy in colon cancer”, International Journal of Molecular Sciences, vol. 21, no. 8.

- Fernández-Ronco, M.P., De Lucas, A., Rodríguez, J.F., García, M.T., Garcia, I. 2013. New considerations in the economic evaluation of supercritical processes: Separation of bioactive compounds from multicomponent mixtures. Journal of Supercritical Fluids, 79:345-355.

- Fernández, C.M., Ramos, M.J., Pérez, Á. & Rodríguez, J.F. 2010, “Production of biodiesel from winery waste: Extraction, refining and transesterification of grape seed oil”, Bioresource technology, vol. 101, no. 18, pp. 7019-7024.

- Fernández, C.M., Solana, M., Fiori, L., Rodríguez, J.F., Ramos, M.J. & Pérez, Á. 2015, “From seeds to biodiesel: Extraction, esterification, transesterification and blending of Jatropha curcas oil”, Environmental Engineering and Management Journal, vol. 14, no. 12, pp. 2855-2864.

- Fernández-Ronco, M.P., Gracia, I., Zetzl, C., De Lucas, A., García, M.T. & Rodríguez, J.F. 2011, “Equilibrium data for the separation of oleoresin capsicum using supercritical CO2: A theoretical design of a countercurrent gas extraction column”, Journal of Supercritical Fluids, vol. 57, no. 1, pp. 1-8.