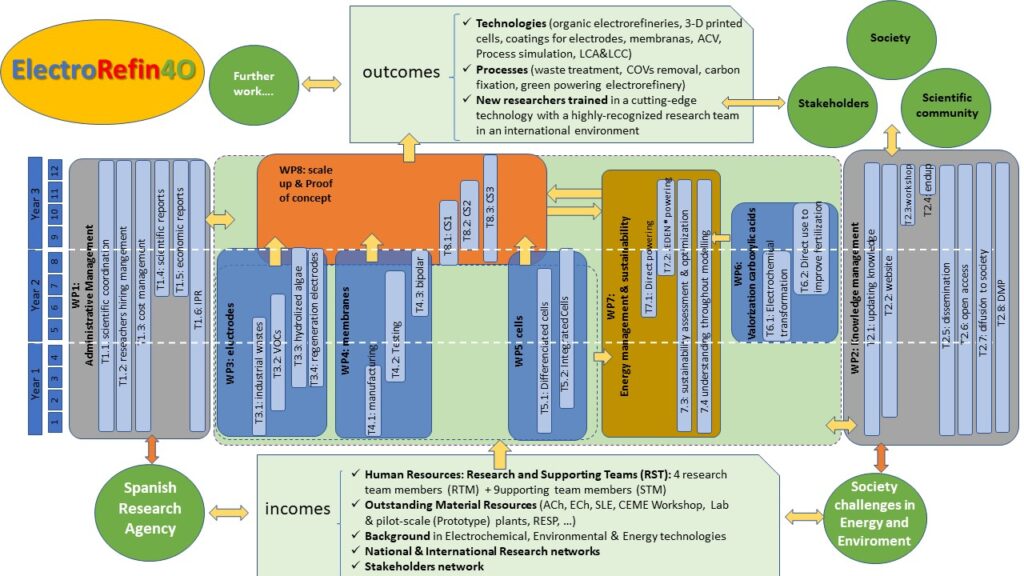

| WP1. TECHNICAL COORDINATION & ECON. MANAGEMENT | |

| B&O: This WP entails all the coordination actions between members of the RST and the stakeholders. The two PIs of the project have leaded many previous regional, national and EU projects, as well as companies contracts. Because of that, they are experienced in coordination actions and the activities proposed in this WP, together with those of WP2, will assure a well-controlled flow of knowledge within ElectroRefin4O. On the other hand, the more and more time-consuming administrative duties related to the research management of a project have oblied to quantify the time efforts dedicated to this administrative work.All is considered in WP1 and consists of: (1) selection and hiring of ESRS; (2) economic tracking of the activities; (3) writing technical and economic reports. | R: MAR |

| 1.0 pm | |

| IP:Q1-Q12 | |

| T1.1: Management of Scientific Coordination. T1.2: Hired researchers management. T1.3: Cost management. T1.4: Preparation of scientific and technical follow-up reports for the Spanish Agency of Research. T1.5: Preparation of economic follow-up reports for the Spanish Agency of Research. T1.6: Intelectual property management. | |

| WP2. KNOWLEDGE MANAGEMENT | |

| B&O: In this WP, all dissemination and technology transfer activities are included, as well as other ways of valuing of the obtained results for the Society. To reach this goal, there are several tasks that go from the development of a website aimed to spread knowledge to Society (inlcuding social networks like twitter and linkedin) up to the organization of the Workshop ElectroRefin4O, that aims to integrate research groups and stakeholders into a discussion forum on the most recent progress, looking for internationalization, knowledge transfer and to show outcomes to Society. It also includes scientific coordination meetings not only among researchers but also with supporting stakeholders and other external companies or organizations interested. It also includes the coordination of the scientific dissemination in scientific meetings, the compilation of research works into the ZENODO repository and the selection of publications which are worth to be golden-access, to satisfy the open acces requirements without charging excessively the budget. As well, howour RTM and STM will participate in diffussion activities including gender issues. Special attention is paid to Data Management Plan to ensure that research data can be used, reused & distributed. | R: JLB |

| 1.0 pm | |

| IP: Q1-Q12 | |

| T2.1: Coordination of knowledge obtained in the project. T2.2: Website & social networks development and maintenance. T2.3: Organization of an international scientific Workshop with sessions opens for general society. T2.4. Final report and preparation of next proposals. T2.5: Dissemination coordination. T2.6. Open access dissemination of research outcomes. T2.7. Planning and articipation in social-scientific events (SSE). T2.8. Data Management Plan. | |

| WP3. DEVELOPMENT OF ELECTRODES FOR PREVENTING MINERALIZATION OF ORGANIC WASTES | |

| B&O: This WP is commited to the development of electrodes (coatings of mixed metal oxides onto different substrates) that promote formation of carboxylic acids and prevent mineralization during the oxidation of organics. As well, it will be searched the formation of polymers with low adhesion capacity to electrodes and that can be easily removed by filtration. TRL level aimed for this WP is 4 (Built in a laboratory environment) and, considering that, a 3-D printed simple-compartment electrochemical cell will be used. This cell is a desing of the E3L lab that has demonstrated very good performance in previous studies and that promotes a flow pattern that prevents the deposit of polymers on the electrode surface while keeps a very important turbulence minimizing mass transfer limitations. Three models of wastes will be fed, trying to obtain relevant data for the three applications that are looked for in this project. 1) model 1: Wastes polluted with mixtures of phenolic species,as representative of non biodegradable industrial wastes produced in chemical industries 2) model 2: solutions containing mixtures of several methyl-benzenes, as representative of the wastes produced during electrochemically assisted absorption processes of gaseous streams containing VOCs and 3) model 3: solutions containing thermal hydrolizates of algae suspensions, in order to develop a new application for carbon sequestration and valorization combining bio and electrochemical processes. Coatings tested will be mixtures of ruthenium, iridium, tin oxides trying to minimize the use of noble metals. They will be compared to three commercial formulations of MMO anodes (de Nora). A last task is included for the recovery of these metals from the spent electrodes and the use in new formulations (which can become a paradigmatic example of circular economy). Selectivity to prevent mineralization & service lifetime define the targets looked for. | R: ELF |

| 4.0 pm | |

| OE: 5 RSP TRL: 4 | |

| IP: Q1-Q8 | |

| T3.1. Development of electrodes for the degradation of phenolic compounds. T3.2. Development of electrodes for the degradation of VOCs. T3.3. Development of electrodes for the degradation of hydrolized algae solutions. T3.4. Recovery of noble metals from spent electrodes. | |

| WP4. DEVELOPMENT OF MEMBRANES FOR AN EFFICIENT ELECTRODIALYTIC SEPARATION OF CARBOXYLIC ACIDS | |

| B&O: The aim of this WP is the development and testing of membranes for an effective separation by electrodialysis of carboxylic acids from the electrolytic reaction mixtures in which they are formed. TRL level aimed for this WP is 4 (Built in a laboratory environment) using commercial membranes from external suppliers and in-house membranes especially taylored for the separation of carboylic acids using the experience gained in membrane manufacturing in the projects asepham/eden/cistem. Different mixtures of low molecular weight carboxylic acids will be used as model solutions trying to evaluate the selectivity of the process at different cell voltages and flowrates distribution. Considering the low TRL, a 3-D printed cell with an-inhouse design already made in the E3L lab is to be used in this WP. This design minimizes the gaps in the cell, favours gas release and promotes turbulent flow patterns while protecting mechanically the membrane. As cathionic membranes nafion type with different thickness will be evaluated. Target for cationic membranes will be only large service lifetime and minimization of crossover. As anionic membranes, three commercial membranes obtained from manufacturers (Fumatech, Neosepta, PCA) will be used as references to compare performance with membranes made by solution blend of polyvinylidene fluoride (PVDF) and polymethyl methacrylate-co-polychloromethyl styrene (PMMA-co-PCMSf). Target for anionic membranes include selectivity towards carboxylic acids as well aslong service lifetime and prevention of crossover. Commercial bipolar membranes will also be evaluated in this WP. Separations of the electrolytically-produced carboxylate mixtures produces in WP will also be assessed using the best membranes produced. | R: JLB |

| 4.8 pm | |

| OE: 3 RSP TRL: 4 | |

| IP: Q1-Q8 | |

| T4.1. Development and characterization of anionic and cationic membranes. T4.2. Testing and comparison of performance with standards for the electrodialytic separation of carboxylic acids. T4.3. Integration of commercial bipolar technology. | |

| WP5. DEVELOPMENT OF 3-D PRINTED ELECTROCHEMICAL CELLS | |

| B&O: Electrochemical cells to improve efficiency in oxidation and separation processes will be developed in this WP using CFD design & 3-D printing with Autodesk software. Starting from the base designs applied in WP3 and WP4, two approaches are aimed in this WP. The first will try to optimize separate cells for the electrolytic and electro-dialytic cells, that will be connected to the same reaction tank and operate simultaneously with the same electrolyte. Here, it is aimed to improve the mechanical design already made in our lab in both cells to improve efficiency, service lifetime of electrodes and membranes and promote the release of gases. The second approach aims to integrate both (the reactive electrolytic and the separation electrodialysis) processes into the same cell. Commercial electrodes and membranes will be used in this WP to optimize time and no changes will be made regardless of the progress in WP3 & 4. TRL level aimed for this WP is 4 (Built in a laboratory environment). It is planned the manufacturing of at least 6 prototypes (3 electrolysis & 3 electrodialysis) for the first approach and other 6 for the second. This does not mean different but sequential prototypes that will be designed, printed, and evaluated in terms of flow dynamics with the Autodesk CFD, Residence Time Distribution, mass transfer coefficients and performance with the three target wastes. | R: MAR |

| 4.1 pm | |

| OE: 2 RSP TRL: 4 | |

| IP:Q1-Q8 | |

| T5.1. Development of differenciated electrolysis and electrodialysis cells for the organic electrorefinery concept. T5.2. Development of integrated electrolysis & electrodialysis cell for the organic electrorefinery concept | |

| WP6. ELECTROCHEMICAL VALORIZATION OF CARBOXYLIC ACIDS TOWARDS HIGHLY ADDED VALUE COMPOUNDS | |

| B&O: In addition to the possibility of direct application to promote the absorption of fertilizers in agriculture and to improve quality of animal feeding products, short chain carboxylic acids are highly soluble in water, as well as in other solvents like methanol, and can be used as bricks for the manufacturing of valuable species within the whole concept of refinery. The goal of this WP is a first evaluation of the transformation of the product streams obtained in the treatment of the three model of wastes that have been selected as target of this project into valuable compounds using electrosynthesis technology. Reductive processes looking for the transformation into less oxidized species (alcohols) is the main target. It is not very aggressive but it has to be considered that this project aims to be a first step and this WP is planned only to elucidate if further work is worth. As well, it is going to be tested the direct use as promoters of the absorption processes, which is considered very important for several stakeholders of the project. TRL level aimed for this WP is 4 (Built in a laboratory environ). | R: JLB |

| 2.7 pm | |

| OE: 2 RSP TRL: 4 | |

| IP: Q4-Q10 | |

| T.6.1 Prospective evaluation of the electrochemical production of highly value products from carboxylic acid solutions T6.2 Application of mixtures of carboxylates to improve fertilizer action. | |

| WP7 ENERGY AND SUSTAINABILITY MANAGEMENT | |

| B&O: In the last projects of our group (mainly in PID2019-107271RB-I00), different possibilities for powering the electrolytic remediation of gases, water and soil with renewable energy have been optimized using in-house software tools and storage of surplus energy in Redox Flow Batteries (RFB) and a chloralkali hydrogen storage system called EDEN® (CTQ2017-91190-EXP) that we are still developing in the frame of different on-going projects. In this WP, we intend to go another step beyond, applying all the technology innovations made to our new electrochemically assisted organic refinery developed in the project, as well as studying the influence of power supply with variable patterns in operation, in a systematic way (defining two behavior profiles: winter, summer) that will be applied for periods of two weeks. In addition, all the technologies developed will be analyzed as a whole, throughout the use of eco-efficiency tools, carbon footprint analysis, energy analysis and the evaluation of uses of the different by-products, to determine what is needed to achieve optimal technology not only from the viewpoint of economy but also of sustainability. WP TRL level aimed is 5 considering that we are using real data | R: CMF(2.8 pm) |

| 5.3 pm | |

| OE: 10 RSP TRL: 5 | |

| IP: Q1-Q11 | |

| T7.1 Direct renewable powering. T7.2 Regulation of the power supply of the electrochemical remediation systems based on EDEN® technology. T7.3. Analysis and optimization of Sustainability. T7.4 Understanding throughout modelling. | |

| WP8 SCALE UP OF THE DEVELOPED TECHNOLOGIES TO THE PROOF OF CONCEPT | |

| B&O: This project does not aim only to develop and test the feasibility the concept of organic electrorefinery but it tries to go further with its application to three cases of study, for which it is required process integration and scaling up and will give important information for the analysis of sustainability of WP7. The three cases involves the treatment of industrial wastes polluted with biorefractory species, the treatment of VOCS and the transformation of carbon dioxide into mixtures of carboxylic acids. In this WP, it is aimed to face the scale up of the three processes according to the optimized conditions found in WP3-WP6. TRL level aimed for this WP is 5 (Tested in intended environment) reaching if possible 6 (Tested in intended environment close to expected performance) considering that we aim to transcend from lab to companies, as we have done before in previous proposals. The three cases of studies will be made with real feeding (real industrial waste, COVS obtained from electroabsortion units treating realistic COVS mixtures in gases and microalgae culture) and include the scale up by manufacturing using 3-Dprinting and testing stacks of cells (with at leat 4 cells) that at least allow to treat in continuous mode flowrates (tests in previous WP are planned as discontinous) and integrated in the proof of concepts all the auxiliary units, including the powering with renewable energies. There is previous experience of the RTM in scaling up and in the operation of large-scale infrastructures. | R: MAR |

| 3.8 pm | |

| OE: 3 RSP TRL: 5-6 | |

| IP: Q8-Q12 | |

| T8.1 Process Integration and Scale up of case of study 1: industrial wastewater. T8.2 Process Integration and Scale up of case of study 2: VOCs. T8.3 Process Integration and Scale up of case of study 3: bio-electrochemical carbon dioxide fixation. | |